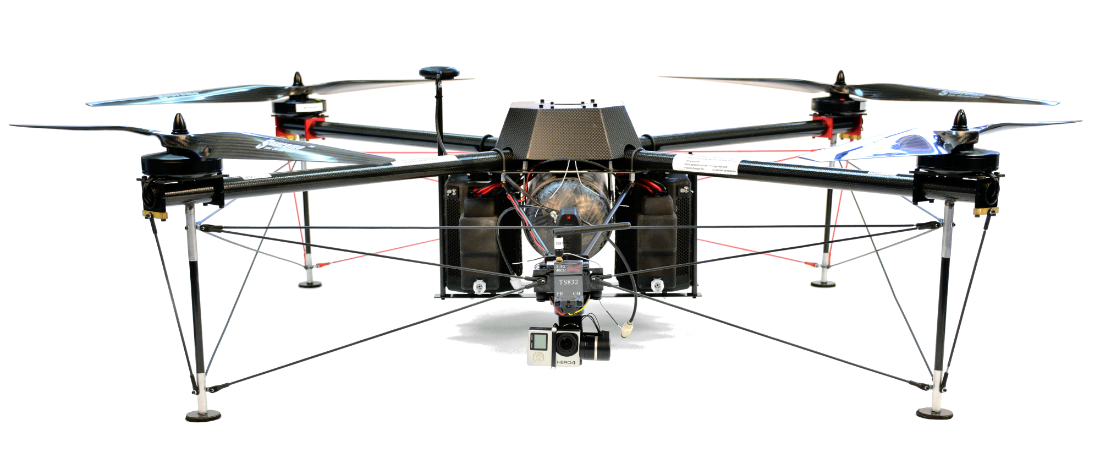

H2QUAD 1000

LONGEST MULTIROTOR FLIGHT ENDURANCE IN THE WORLD

2 HR FLIGHT ENDURANCE WITH 1 KG PAYLOAD

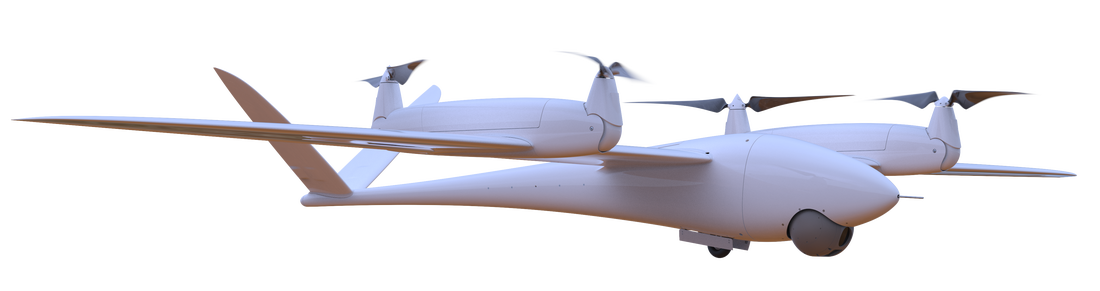

TRON H2

VERTICAL AND HORIZONTAL FLIGHT

UP TO 8 HOUR ENDURANCE

POWERED BY FUEL CELL

(COMING SOON)

EPAC

ENERGY & POWER ANYWHERE-CONTINUOUSLY (APU)

DESIGNED SPECIFICALLY FOR FIELD APPLICATIONS

CUSTOM SYSTEMS DEVELOPMENT

ENERGYOR CAN DELIVER FUEL CELL SYTEMS THAT ARE TAILORED TO YOUR SPECIFIC REQUIREMENTS

H2QUAD 400

DESIGNED SPECIFICALLY TO DELIVER EXTENDED FLIGHT ENDURANCE.

3 HR 45 MN ENDURANCE (2014)

SEE OUR DRONE IN MILITARY OPERATION.

Watch EnergyOr's H2QUAD 1000 drone fly in a french military operation